Fully Automatic Non Woven Doctor cap making machine

Product Details:

| Place of Origin: | China |

| Brand Name: | RT |

| Certification: | CE |

| Model Number: | DH-GY6 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Packaging Details: | Wooden Pallet /wooden case |

| Delivery Time: | 7-15 days |

| Payment Terms: | TT |

| Supply Ability: | 200 units /month |

|

Detail Information |

|||

| Material: | Aluminium Alloy Frame | Cap Size: | Vesatile |

|---|---|---|---|

| Machine Frame: | Optional: Aluminium Alloy/painted Steel | Material: | Both Nonwoven & PE |

| Aplication: | Hospital, Medical, Surgial , Hotel, Dust-free Plant | Product Size: | 3 Sizes On One Machine Without Change Mold |

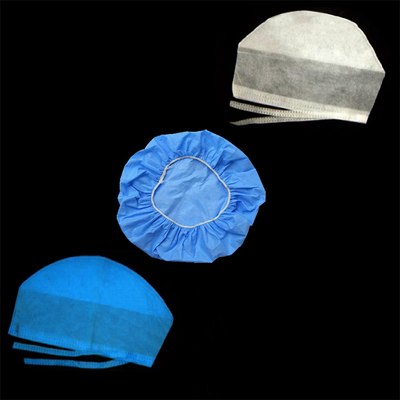

| Product Type: | Bouffant Cap, Shower Cap,food Cover,beard Cover, Ear Cover, Micro Phone Cover | Control System: | Optional : Touch Screen / Button Pannel |

| Packing Method: | Optional With Automatic Packing Unit | Elastic Type: | Double Elastic / Single Elastic |

Product Description

Application

The fully automatic medical cap making machine is made of aluminum alloy frame, which is lighter and firmer. This machine can weld mask earrings. It is a fully automatic production machine from raw material supplying to finished doctor cap output.

Main Features

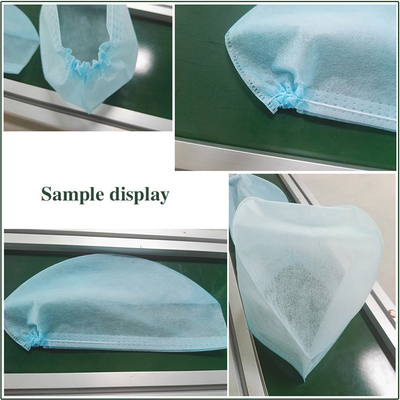

- With ultrasonic welding method this machine can make the non-woven fabric folding into a doctor's cap.

- The man-machine interface operation requires only one person. The inside PLC program control system, make the machine high stability, low failure rate. And the imported deceleration brake motor make it effectively reducing the product's defective rate.

- Adjustable tension system control ensures the beautiful appearance of the finished product.

- With the automatic feeding detection system, the machine will automatically stopped when roll material running out, so that the machine will not idling.

Specification

| Model | DH-GY6 |

| Dimension( mm) | 8800×900×1650mmmm (L*W*H) |

| Speed | 90~ 120pcs/min |

| voltage | 220V/380V(can be customized as request) |

| Total power | 11.8kw |

| weight | 1880Kg |

| Finished product size | 3150*1150MM (other size can be customized) |

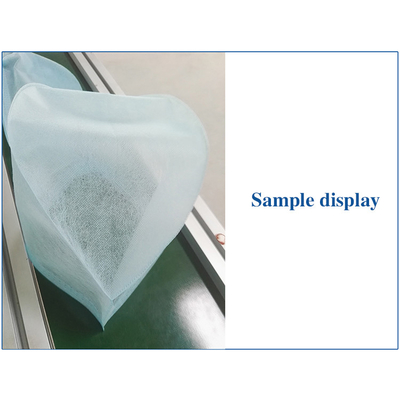

Production Process:

Automatic feeding -import- folding - welding - forming and cutting to output